MANAGE BRAND COLORS

COLOR CONSISTENTY & HIGH QUALITY GRAPHICS

INK SAVER TECHNOLOGY

LESS INK - NO VISUAL LOSSES IN QUALITY

PROCESS AUTOMATION

AVOID ERROS & SAVE MONEY

Save time, money & maintain color consistency

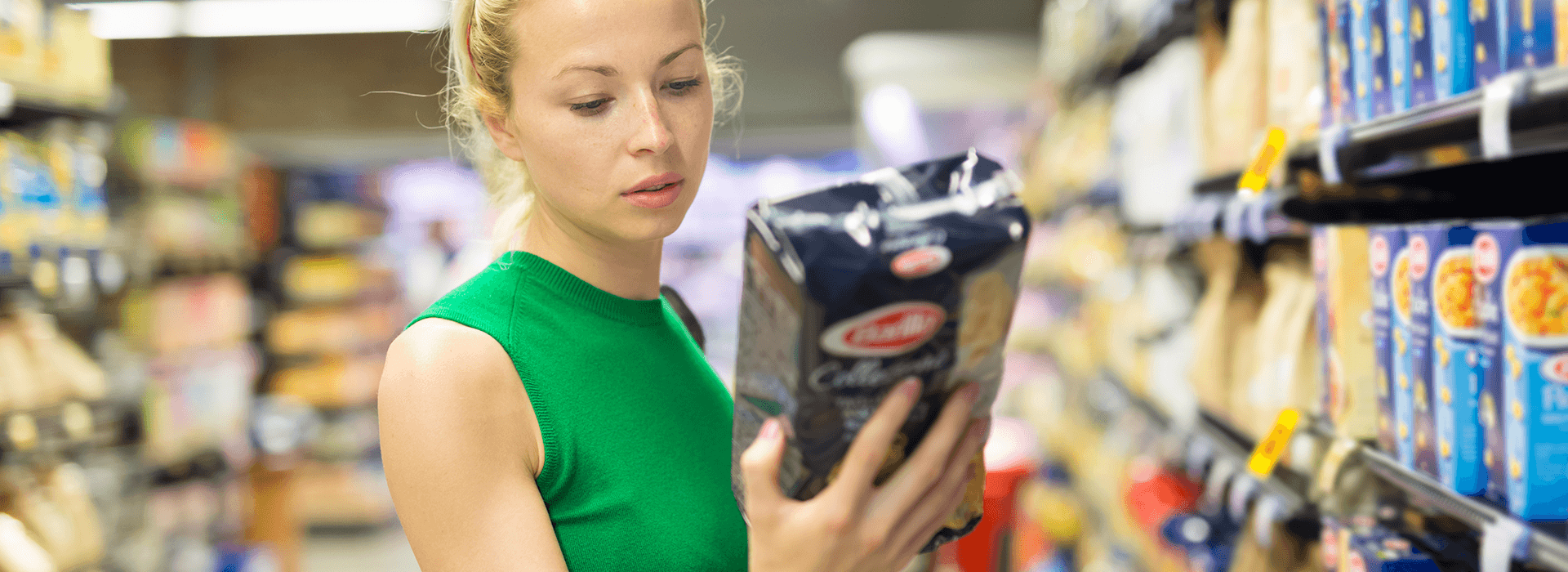

Achieving high-quality results in packaging printing is a challenge for any company looking to stand out in today's competitive marketplace. It is not easy to capture the consumer's eye while conveying the value of the product.

To achieve these goals, it is essential to lean on efficient tools that can streamline the production process while ensuring consistent results.

ColorGATE Packaging Productionserver offers many benefits that will take your packaging production to a new level, such as our Fingerprint module, which improves your printing workflow by enabling exact color definitions, archiving print production data and printing exact reproductions at any time.

Our software is ideal for achieving reliable results on different presses and under different printing conditions, while reducing material and labor costs.

Learn more from our experts and stand out in today's market:

Application Areas

- Direct-to-Object

- Bottles & glasses

- Cans, tins, tubes

- Container

- Flexible packaging

- Labels & sleeves

- Folding Carton

- Corrugated

WHAT WE HAVE TO OFFER

MANAGE BRAND COLORS

With our color management tools, we guarantee a precise and consistent color reproduction, regardless of the material: paper, labels, corrugated board or direct-to object! Plus, we also support spot colors using the Spectral Spot Module, as long as you have a PantoneLIVE account.

INK SAVER TECHNOLOGY

With our Ink Saver Technology, you can reduce your ink consumption and achieve up to 30% savings in ink costs. This innovative technology not only maintains visualy the same high-quality standards for your prints, but also results in shorter drying times.

PROCESS AUTOMATION

Our advanced automation solutions not only make your production chain less susceptible to errors, but also save you time and money allowing you to overcome any upcoming color management challenges.

Technical Details

Basic functions

Media-Ink-Metamode (MIM)

- ColorGATE development to create production-influencing parameters such as medium (M), ink (I) and metamode (M); every MIM combination links profile, linearization and print mode settings into a single logical unit

- MIM administration: import, export, administration and processing of MIM combinations

ICC color management with CrossXColor Technology

- Use of rendering intents (options: Photographic; Perceptual; Absolute perceptual; Relative colorimetric; Absolute colorimetric; Saturation; Absolute compression; Blackpoint compensation; Lightener compensation; Minimal white compensation)

- Use of embedded ICC profiles in JPEG, TIFF, PDF, PSB and PSD files for use as input color space; embedded Output Intents can be used

- Multicolor ICC Engine: Support of multicolor ICC profiles with up to 15 color channels

- ColorGATE GamutPlus: Enhanced CMYK input color space, based on ISOcoated_V2 for a more color intensive output

16-Bit Color Rendering

For a higher color accuracy and smooth gradientsPreservation of pure colors

Preservation of black, CMYK or single CMYK channels as pure colorsVarious options for color correction

- Correction of brightness, contrast and gamma

- Gradation curves

- Separate or simultaneous channel processing possible

Saturation enhancement

To increase the saturation of output colorsGamut Viewer

Two- and three-dimensional (2D/3D) visualisation and comparison of color spacesSpecial color printing (white/varnish/metallic; printer-dependent)

- Support of white, varnish and metallic printing (on appropriate printing systems)

- Output variants: pixel, filling, selective, flood, spot color, including preview, and others

- Combination of process colors, silver metallic ink and white ink

- Layering technology

- Separate gradation curves possible

- Spread and Choke: overlap/border filling adjustable for special colors

- Intensity: adjustable intensity/density of the white or special color channel

- Preview for white print

Preview (full screen, split, thumbnail, softproof)

- Document view, placement on output media, rotated view, full screen preview, preview with special colors

- Split: before and after display for visualization of changes

- Thumbnail: job thumbnails, display of job properties

- Softproof: simulation of the print output on screen, merging of separated PDF files

Loading of media size (printer-dependent)

- Available for e.g. HP-DesignJet-Z series, Roland AJ, FP, VP, XC, XJ and various Epson Stylus Pro printers

- Automatic or manual

Confidence strip

- Printing of a confidence strip with the color channels used to ensure a consistent printout

- Different positions and sizes possible

Various scaling options

- Proportional/non-proportional scaling in height, width, percent

- Automatic scaling to media size

- Visual scaling: proportional scaling by means of a distance tool

Copy and layout print

- Job repetetion, multiple output with only one RIP process, last row filling (better media utilization)

- Device handled creation of multi-copies, in which the parameters are transferred from the RIP to the device controller (printer-dependent)

Cropping

Definition of print areasRotate and mirror

- Rotate in 90° steps

- Jobs can be rotated space-optimized, even automatically

Offset and centering

- Horizontal/vertical offset adjustment

- Centering on sheets and rolls

Auto tiling

Automatic segmenting for printing oversized jobs with optional overlapCut marks and registration marks

- Printing of cut and registration marks

- Style: inner/outer marks, inner/outer frames, japanese marks; different line widths, styles and colors; can be placed on PDF TrimBox via function

- Dimensions: symmetrical/asymmetrical adjustment of distance and length

FOTOBA and FLEXA cut marks

- Printing of special cut marks for FOTOBA or FLEXA cutting systems (for the output of containers, the TNM is required)

- Separate adjustment of distances and lengths

Overlap/Tiling marks

- Horizontal/vertical distance and width/height adjustable

- Optional marks or solid lines

Eyelet marks

- Eyelet style, offset, distance, number, color, diameter and thickness adjustable

- Optional crosshair printing

Printing of job information

- Free to formulate

- Contain e.g. EXIF data, input profils or the print date

- Freely defineable formatting settings, e.g. position, font type, size and color

Anti Aliasing (printer-dependent)

Enhanced print quality for certain printers with low resolutionInterpolation for raster files

- Various setting options for interpolating raster files such as TIFF, JPEG, etc.

- Options: Nearest neighbour, Bilinear, Bicubic, Bicubic sharp

Replacement of missing fonts

Detection of missing fonts and optional replacement with CourierMedia compensation

Compensation of length and width deviations in the output formatSelection of various screens

- FM - frequency modulated (Speed Screen, Frequency Screen, ColorGATE Crispy, ColorGATE Smooth, Floyd-Steinberg, Error Diffusion, Error Diffusion Smooth)

- AM - amplitude modulated (Custom Screen, Super Rosette 2)

- Hybrid - combination of AM and FM screening (Hybrid Screen 2)

JobInfoLog (monitoring of job processing)

Monitoring/logging of job processing, display of job- and event-related information, of print time, print speed and print area, warning e.g. of missing fontsRIP and print simultaneously/automatically

- Printing the job while RIP process is running

- RIP/print automatically executable

Various options for job processing

- Reproduction of already printed jobs without a new RIP process

- Processed print jobs are optionally deleted automatically (different options possible)

- Automatic pause after each print job / manual confirmation of the release for each print job

Flexible management of job queues

- Importing/Positioning jobs using Drag&Drop

- Simultaneous moving of multiple jobs within the job, RIP and printer queue

- Job sorting according to numerous criteria possible, free definition of column type/number, automatic placement of new jobs to the correct position within the queue

Quick assignment of hotfolder settings

- Transfer of hotfolder settings to individual jobs via mouse click

- Possible for individual tabs as well as for all settings

Job duplication

- Duplicating jobs

- Creating links to other jobs

Sending jobs to other open printers

Transfer of an existing job including appropriate settings to another printer definitionSupport of virtual printers

- For transferring print jobs out of an application

- Including export of configuration specific PPD's (PostScript Printer Definitions) under PC/Mac/Unix

Backup/Restore of RIP configuration

Backup and restore of the current RIP configuration including program settings, printer definitions, jobs, profiles, etc.Cutting function support for hybrid devices (only with PCM, printer-dependent)

Support of print and cut workflows for printing systems with an integrated cutting functionDisplay of color information (Color Picker)

- CMYK percentage values displayed in full screen preview

- Measured color can be replaced

Printer Status Monitor (printer-dependent)

- Display of e.g. ink level, media length, warnings/error messages

- Available for e.g. HP Z series, Roland AJ, FP, VP, XC, XJ and various Epson Stylus Pro or Canon printers

System languages

- Chinese (simplified), English, French, German, Greek, Italian, Japanese, Russian, Spanish

- For following languages a basic localization is available: Chinese (traditional), Finnish, Korean, Norwegian, Polish, Portuguese

File formats

Support of raster file formats

- BMP, JPEG, TIFF, PNG, PSB, PSD

Support of PDF, PS, EPS

- Adobe PDF 1.7, PDF/X-1a, PDF/X-3, PDF/X-4, PDF/X-5 and PDF/VT

- Postscript 3, EPS, DCS 2.0

- Single-page/multi-page and separated possible

System requirements

Operating systems (64-Bit):

Minimum hardware requirements:

Recommended for using one printer:

Recommended for using multiple printers:

Installation and operation:

USB port for USB dongle required; LAN adapter, TCP/IP for network access required, licenses with soft key require internet access (the software must connect to license server approximately once per day)Supported interfaces (depending on used printers, measuring devices and cutting plotters):

Ethernet, TCP/IP, USB, FireWireUse in virtualized environments:

Licenses with soft key:

Operation of the ColorGATE software on virtual machines is not permitted with licenses with soft key.

Licenses with USB key:

If the virtualization solution supports USB, ColorGATE software can usually be operated with licenses with USB key. Please note, however, that ColorGATE cannot provide support for problems that occur in the context of the virtualization solution. There may be restrictions when printers, measuring devices or cutting plotters are connected via USB. In addition, the hardware requirements must be exclusively available as resources for the virtual machine to ensure a high-performance operation of the software. For these reasons, we recommend using virtualized environments for testing purposes only.