CHEMICAL-FREE PRODUCTION

ECO-FRIENDLY & COST-EFFECTIVE

STREAMLINED WORKFLOW

LESS LABOR REQUIREMENTS

HIGH-QUALITY RESULTS

PRECISION IN EVERY PIXEL

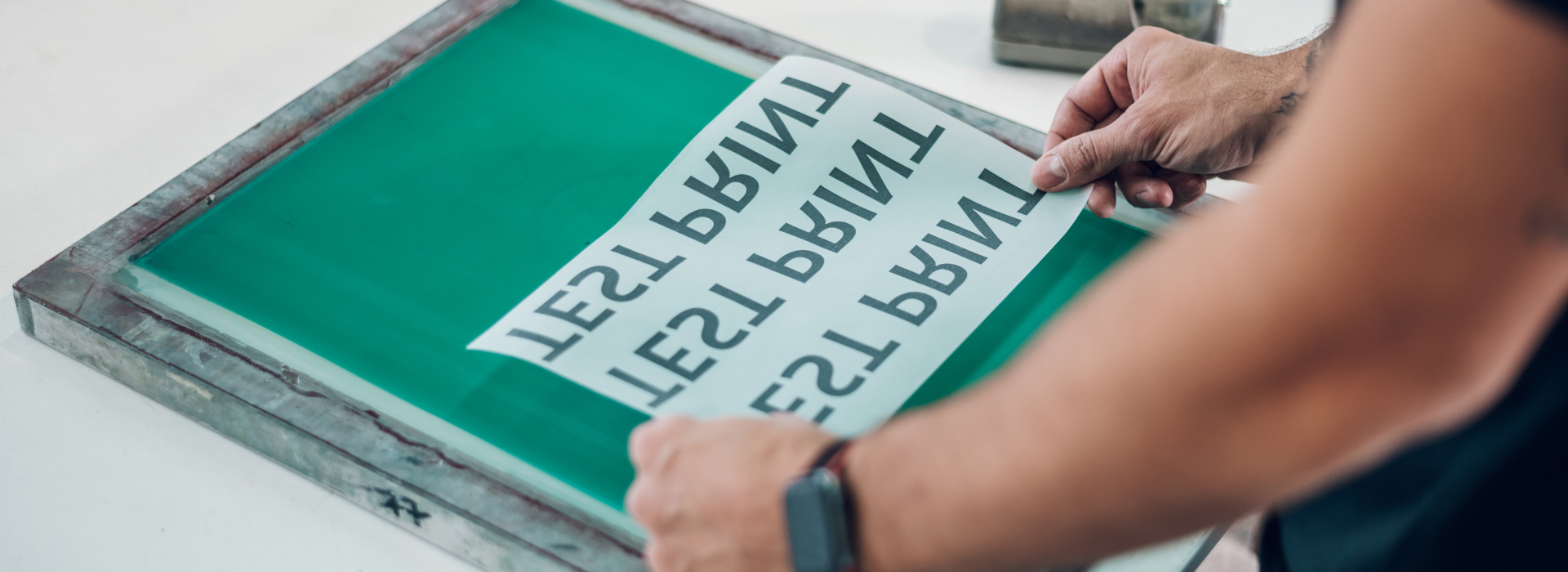

CREATE CHEMICAL-FREE FILMS!

Join us in redefining film production - experience the chemical-free creation of high-quality halftone films using inkjet printers that not only streamline the process, but also make it safer and more environmentally friendly.

With Filmgate, you can eliminate the exposure and development steps, reducing labor and saving time. The results are impressive, with the ability to achieve up to 70 lines per centimeter or 180 lpi, ensuring sharp and detailed images on your films. Compatible with multiple printing methods, it offers customizable screens and simplified workflows with MIM technology that supports spot colors. In addition, you can access the appropriate film material directly from ColorGATE.

Discover the future of film production with Filmgate, where innovation, efficiency and quality are paramount! The functionality of Filmgate is also available as a module for Productionserver: The Film and Plate Module.

WHAT WE HAVE TO OFFER

CHEMICAL-FREE PRODUCTION

Filmgate transforms film production, eliminating chemicals for a safer and eco-friendly process, making your prints cleaner and greener, while keeping a high-quality with inkjet printers.

STREAMLINED WORKFLOW

Experience a more efficient workflow with Filmgate, removing exposure and development steps, reducing labor, and saving valuable time and money.

HIGH-QUALITY RESULTS

Enjoy precision in every pixel, delivering stunning results with up to 70 lines per centimeter / 180 lpi for sharp and detailed images.

Technical Details

Basic functions

Various separation options

- Automatic creation of CMYK separations

- Conversion of embedded spot colors into CMYK separations

- Automatic deactivation of all separations except for black (K) for composite files so that only the black plate is printed

- Creation of separated print jobs from each separation of a file

- Transformation of each separation into a negative output; info text, cut marks and registration marks will also be printed inversely

ICC color management for separation creation

- Separation creation based on selectable or embedded CMYK ICC profiles

- Selectable rendering intents for RGB to CMYK conversions

Media-Ink-Metamode (MIM)

- ColorGATE development to create production-influencing parameters such as medium (M), ink (I) and metamode (M); every MIM combination links profile, linearization and print mode settings into a single logical unit

- MIM administration: import, export, administration and processing of MIM combinations

16-Bit Color Rendering

For a higher color accuracy and smooth gradientsLinearization adjustment

- Ink level adjustment, if necessary adding ink for density adaption of screen printing films

- Ink reduction curves for variable adjustment of the ink values to tonal values

- Adjustment of the linearization of screen separations via densitometric (% dot) measurements

- Linearization per channel, includes the dot gain limitation

- Optimization of linearization through multiple output and measurement of the calibration target; each with recalculation of the linearization curve

Various options for color correction

- Correction of brightness, contrast and gamma

- Gradation curves

- Separate or simultaneous channel processing possible

Dot gain correction

- Correction of the dot gain up to +/- 40% for all or single separations or calculation of tonal value curves from a given ICC profile

Redirect printheads

- Print data redirection of a color to any available print head

- For special film printers which are charged with multiple K cartridges, the active print head can be selected

Display of color information (Color Picker)

- CMYK percentage values displayed in full screen preview

- Measured color can be replaced

Selection of various screens

- Custom Screen: free definition of screen angles, dot forms and line resolutions

- Super Rosette 2: sharped-edged, homogenous printed images resulting from screen angles of the highest precision

- Frequency Screen: frequency modulated screen with controllable dot size

- Hybrid Screen 2: combines the advantages of the two screen technologies Super Rosette 2 and Frequency Screen

Various preview functions

- Separations preview: single separated colors of a job in grayscale or process colors

- Full color preview: Colored job preview in composite mode (merging of all separations)

- Output preview of the separation arrangement on the print medium

- Document view, placement on output media, rotated view, full screen preview

- Thumbnail: job thumbnails, display of job properties

Definition of a fixed stencil size

- Defined output area with output of cut marks and indication of protected margins

- Also for copy and layout print

Loading of media size (printer-dependent)

- Available for e.g. HP-DesignJet-Z series, Roland AJ, FP, VP, XC, XJ and various Epson Stylus Pro printers

- Automatic or manual

Confidence strip

- Printing of a confidence strip with the color channels used to ensure a consistent printout

- Different positions and sizes possible

Various scaling options

- Proportional/non-proportional scaling in height, width, percent

- Automatic scaling to media size

- Visual scaling: proportional scaling by means of a distance tool

Copy and layout print

- Job repetetion, multiple output with only one RIP process, last row filling (better media utilization)

- Device handled creation of multi-copies, in which the parameters are transferred from the RIP to the device controller (printer-dependent)

Cropping

Definition of print areasRotate and mirror

- Rotate in 90° steps

- Jobs can be rotated space-optimized, even automatically

Offset and centering

- Horizontal/vertical offset adjustment

- Centering on sheets and rolls

Cut marks and registration marks

- Printing of cut and registration marks

- Style: inner/outer marks, inner/outer frames, japanese marks; different line widths, styles and colors; can be placed on PDF TrimBox via function

- Dimensions: symmetrical/asymmetrical adjustment of distance and length

Printing of job information

- Free to formulate

- Contain e.g. EXIF data, input profils or the print date

- Freely defineable formatting settings, e.g. position, font type, size and color

Interpolation for raster files

- Various setting options for interpolating raster files such as TIFF, JPEG, etc.

- Options: Nearest neighbour, Bilinear, Bicubic, Bicubic sharp

Replacement of missing fonts

Detection of missing fonts and optional replacement with CourierMedia compensation

Compensation of length and width deviations in the output formatJobInfoLog (monitoring of job processing)

Monitoring/logging of job processing, display of job- and event-related information, of print time, print speed and print area, warning e.g. of missing fontsVarious options for job processing

- Reproduction of already printed jobs without a new RIP process

- Processed print jobs are optionally deleted automatically (different options possible)

- Automatic pause after each print job / manual confirmation of the release for each print job

Flexible management of job queues

- Importing/Positioning jobs using Drag&Drop

- Simultaneous moving of multiple jobs within the job, RIP and printer queue

- Job sorting according to numerous criteria possible, free definition of column type/number, automatic placement of new jobs to the correct position within the queue

RIP and print simultaneously/automatically

- Printing the job while RIP process is running

- RIP/print automatically executable

Quick assignment of hotfolder settings

- Transfer of hotfolder settings to individual jobs via mouse click

- Possible for individual tabs as well as for all settings

Job duplication

- Duplicating jobs

- Creating links to other jobs

Sending jobs to other open printers

Transfer of an existing job including appropriate settings to another printer definitionPrinter Status Monitor (printer-dependent)

- Display of e.g. ink level, media length, warnings/error messages

- Available for e.g. HP Z series, Roland AJ, FP, VP, XC, XJ and various Epson Stylus Pro or Canon printers

Support of virtual printers

- For transferring print jobs out of an application

- Including export of configuration specific PPD's (PostScript Printer Definitions) under PC/Mac/Unix

Backup/Restore of RIP configuration

Backup and restore of the current RIP configuration including program settings, printer definitions, jobs, profiles, etc.System languages

- Chinese (simplified), English, French, German, Greek, Italian, Japanese, Russian, Spanish

- For following languages a basic localization is available: Chinese (traditional), Finnish, Korean, Norwegian, Polish, Portuguese

File formats

Support of raster file formats

- BMP, JPEG, TIFF, PNG, PSB, PSD

Support of PDF, PS, EPS

- Adobe PDF 1.7, PDF/X-1a, PDF/X-3, PDF/X-4, PDF/X-5 and PDF/VT

- Postscript 3, EPS, DCS 2.0

- Single-page/multi-page and separated possible

System requirements

System requirements

Operating systems (64-Bit):

Minimum hardware requirements:

Recommended for using one printer:

Recommended for using multiple printers:

Installation and operation:

USB port for hardware dongle required; LAN adapter, TCP/IP for network access required, software-based licenses require internet access (the software must connect to license server approximately once per day)Supported interfaces (depending on used printers, measuring devices and cutting plotters):

Ethernet, TCP/IP, USB, FireWireUse in virtualized environments:

Software based licenses:

Operation of the ColorGATE software on virtual machines is not permitted with software based licenses.

Hardware based licenses ("hardware dongle"):

If the virtualization solution supports USB, ColorGATE software can usually be operated with hardware based licenses. Please note, however, that ColorGATE cannot provide support for problems that occur in the context of the virtualization solution. There may be restrictions when printers, measuring devices or cutting plotters are connected via USB. In addition, the hardware requirements must be exclusively available as resources for the virtual machine to ensure a high-performance operation of the software. For these reasons, we recommend using virtualized environments for testing purposes only.